Have you ever paused and wondered how the huge cranes lift tons of steel? Or how your vehicle just halts with a mere touch on the brake? Do you have any idea that behind all these things we see daily, there are two remarkable technologies: hydraulics and pneumatics. You don’t have to be an engineer to know them; you just need a little curiosity and a sense of wonder at how things really work.

In this blog, you’ll get to know the basics of these systems, where you’ll see them in action, their advantages and disadvantages, and how to choose the right one for the job. Whether you’re a student, technician, or just naturally curious, you’ll find something useful here.

In this blog, we’re going to read following topics:

- What is Hydraulics?

- What is Pneumatics?

- Real-World Examples

- Comparison between Hydraulics and Pneumatics

- How Are Hydraulic and Pneumatic Systems Similar?

- What Is One Advantage of Using Pneumatic Power Over Hydraulic Power?

- Making a Choice Between Hydraulics and Pneumatics

- Advantages At a Glance

- Final Thoughts

What is Hydraulics System?

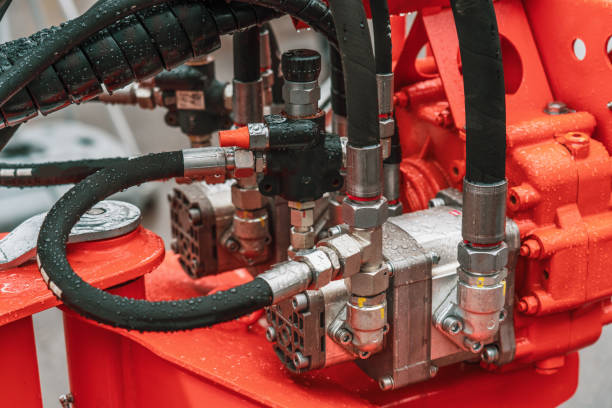

The hydraulic system is a mechanical power system that operates through pressurized liquid, usually oil, to create and transfer force. When you apply pressure to the fluid inside a sealed system, that force moves through the liquid to power machinery or lift heavy loads.

Hydraulics are mostly used in construction equipment, car brakes, aircraft controls, and industrial machines, anywhere strong, controlled movement is needed.

What Is a Pneumatic System?

A pneumatic system is a fluid power application that uses compressed air to generate and control force. Air is stored in a tank and released through valves to move pistons, actuators, or tools. Since air is compressible, pneumatic systems are quick and lightweight, though not as strong as hydraulic ones.

These systems are common in places that need quick, clean, and simple motion, like assembly lines, truck brakes, or dental drills. They don’t offer as much force as hydraulics, but they’re fast and easy to maintain. Since air is easy to get and doesn’t make a mess, pneumatics are a practical choice for a lot of everyday machines.

Read Also: Essential Guide to Hydraulic Repair Services in Chilliwack

Read Also: Different Types of Hydraulic Fittings

Real-World Examples

Getting to know these technologies is easier when you see them at work. Examples from real industries from industries and daily life will help you out!

Hydraulic System

- Construction Equipment: Excavators and bulldozers use this to lift thousands of pounds of material.

- Vehicle Brakes: Cars and motorcycles depend on hydraulic brake systems to safely stop when they are at high speeds.

- Aircraft Controls: Landing gear, wing flaps, and steering in commercial airplanes are run by hydraulics.

- Manufacturing Presses: Hydraulic presses in factories can apply tons of pressure to shape or cut materials.

- Auto Repair Shops: Vehicle lifts and jacks often use hydraulic pressure to elevate cars for repairs.

A hydraulic press can use more than 150 tons of force in a compact space. It is best for metal stamping or forming.

Pneumatics System

- Air Brakes in Trucks & Buses: Trucks and buses use air brakes because they need strong, reliable stopping power to handle the weight they carry, especially on long or steep routes.

- Dentist Tools: High-speed drills use pneumatic power for the right kind of control and easy sterilization.

- Factory Automation: Pneumatic arms and actuators assemble products with speed and accuracy.

- Packaging Lines: Here, they control sealing, labeling, and sorting on high-speed production lines.

- Doors and Gates: Automatic sliding doors in malls and stations usually use compressed air for smooth working.

In the food industry, pneumatic systems are preferred because they don’t have the risk of oil leaks that could pollute products.

Comparison Between Hydraulic and Pneumatic Systems

Take a look at how the two systems are different from each other:

| Feature | Hydraulic System | Pneumatic System |

| Power Medium | Pressurized liquid (mostly oil) | Compressed gas (usually air) |

| Force Output | High, up to 5,000 psi or more | Lower, under 150 psi |

| Speed of Working | Slower, but smoother and more controlled | Fast, best for repetitive actions |

| Precision | High, best for fine-tuned control | Moderate, better for rapid movement |

| Cleanliness & Safety | Risk of leaks and polluting | Cleaner and safer, leaks are just air |

| Applications | Lifting, pressing, braking, and aircraft control | Assembly, automation, dental tools, air brakes |

| Maintenance | Needs more care, especially for fluid integrity | Easier to maintain and fine-tune it |

| Installation Cost | Higher upfront investment | Lower installation and working costs |

| Weight & Portability | Heavier equipment | Lightweight and small |

Both hydraulic and pneumatic systems convey power, but they do differ. Hydraulics utilize pressurized oil to generate strong, controlled force. They’re utilized in heavy-duty work such as lifting, pressing, or braking on big machines. Pneumatic systems use compressed air. They don’t produce as much force but are quicker, lighter and simpler to maintain. Hydraulics are more accurate but require regular maintenance and are more expensive to install. Pneumatics are cleaner, safer, and more suitable for fast, repetitive use, such as in assembly lines, dental equipment, or car air brakes. It comes down to whether you need increased power or increased speed.

How Are Hydraulic and Pneumatic Systems Similar?

Although they use different power mediums, both systems:

- Convert fluid energy into mechanical work

- Use valves, actuators, and pumps/compressors

- Offer remote, reliable control of motion

- Help machines lift, push, rotate, clamp, or hold

They’re the reason why factories, farms, airports, and auto shops can work efficiently every day.

What Is One Advantage of Using Pneumatic Power Over Hydraulic Power?

If safety and simplicity matter more than brute force, pneumatics is most of the time a better choice. One big advantage of pneumatic systems is clean working. Since they use air, there’s no risk of hazardous fluid leaks, making them perfect for environments like food packaging, electronics assembly, or medical offices.

Making a Choice Between Hydraulics and Pneumatics

Let’s say you’re trying to pick the right system for a job. This is how you can go about it:

Go Hydraulic if:

- You need to lift or move heavy loads.

- Your equipment needs accuracy.

- Space isn’t a major issue, and you’re okay with regular fluid maintenance.

Go For Pneumatic in case of:

- Your operation involves fast, repetitive tasks.

- Safety, speed, and cleanliness are top priorities.

- You’re working with a tight budget and limited space.

Hydraulic systems are in strong demand, especially in industries like construction and automotive where raw power and control are absolutely necessary. Experts expect the market to grow significantly over the next few years, approaching the $50 billion mark by 2027. At the same time, pneumatics is carving out a bigger role in fields like food production and electronics. Because these systems use clean, compressed air instead of oil, they’re ideal for environments where hygiene, speed, and low maintenance really matter.

Advantages At a Glance

Hydraulic Systems

- Provides high force for lifting or pressing

- Superb accuracy and smooth operation

- Reliable in hostile environments

- Small components for applications with high power

Pneumatic Systems

- Responsive and fast movements

- Clean and safe, no liquids used

- Easy and inexpensive to maintain

- Optimum for high-cycle operations

Final Thoughts: Which System Is Right for You?

There’s no one-size-fits-all answer. It really comes down to what the system needs to do. Hydraulic systems shine when strength and accuracy are very important. Pneumatics win when safety, speed, and low maintenance matter most.

If you’re unsure which system fits your operation, or if you’re looking for professional servicing, reach out to the team at Delange’s Industries. We’ve helped clients and optimized their hydraulic and pneumatic systems for maximum performance.

People Also Ask

What is Hydraulics?

Hydraulics is a power transmission method that uses pressurized liquids, usually oil to generate and control force. Since liquids are nearly incompressible, hydraulic systems offer high precision and strength. They are commonly used in heavy machinery, industrial equipment, and automotive braking systems.

What is Pneumatics?

Pneumatics uses compressed gases, typically air, to transfer energy and perform mechanical work. These systems are known for their speed, cleanliness, and simplicity. Pneumatics is widely used in automation tools, robotic arms, and machines requiring quick, repetitive motion with lower force.

What is the Difference Between Hydraulics and Pneumatics?

- Medium Used:

- Hydraulics use liquids (usually oil).

- Pneumatics use gases (typically air).

- Compressibility:

- Hydraulic fluids are incompressible, making systems more stable.

- Pneumatic systems use compressible air, allowing faster movement.

- Power & Precision:

- Hydraulics offer higher power and precision.

- Pneumatics are quicker but provide less force.

- System Design:

- Hydraulic setups are generally larger and heavier.

- Pneumatic systems are more compact and lightweight.

What Are the Benefits of Using Hydraulics?

- High Force Output: Easily handles heavy loads with pressures up to 5,000 psi or more.

- Smooth Operation: Fluid motion enables precise and vibration-free performance.

- No Mechanical Complexity: Force is transmitted directly, no need for gears or levers.

- Reliable Performance: Ideal for tough industrial tasks and long-term use.

What Are the Advantages of Pneumatics?

- Compact and Lightweight: Perfect for space-constrained or mobile setups.

- Cleaner Systems: No risk of oil leakage—ideal for clean-room environments like food or pharma.

- Fast Operation: Quick actuation speeds are great for repetitive tasks.

- Simple Maintenance: Fewer moving parts means easier upkeep and fewer breakdowns.