The main types of hydraulic fittings include JIC, NPT, ORFS, BSP, and metric. All of them have different thread standards and sealing methods, which are made for specific pressure ratings and system requirements.

In any hydraulic system, fittings play a big role, and they do more than just hold things together. They keep pressure in and leak out. These systems run hard, and if there is a wrong fitting, it can cause serious problems. For example, it might not seal right, threads could strip, or it just won’t hold up under load.

There is more than one type of hydraulic fitting because different systems have different demands. Some use JIC threads, while others rely on NPT or ORFS. There are British and metric threads too. It all depends on the equipment, pressure range, and sealing style.

You can’t simply guess. You have to match fittings to the system by thread, seal type, and pressure rating. That’s what this guide covers. You’ll know the most common hydraulic fitting types, how they’re built, and where they’re usually used. If you work with fluid power systems, this kind of knowledge makes repairs easier, helps avoid mismatches, and keeps downtime to a minimum.

What Is Hydraulic Fitting?

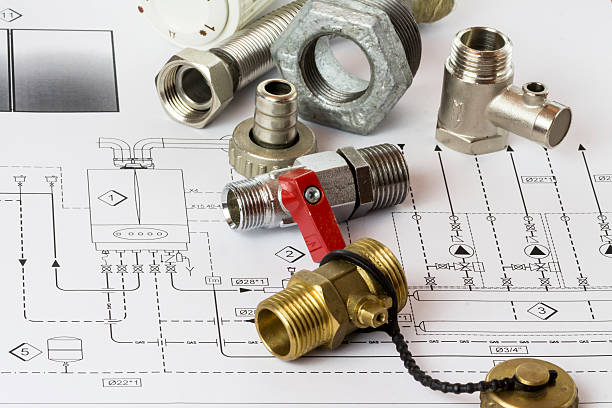

A hydraulic fitting connects hoses, pipes, or tubes in a hydraulic system. Its main job is to create a leak-free seal that can handle high fluid pressure. These fittings come in different thread types and sealing styles, according to their system requirements.

Most fittings are made from steel, stainless steel, or brass so they are able to hold up under pressure and resist rust. They’re used in everything from construction tools and equipment and industrial presses to agricultural machinery and automotive systems. Without the right fitting, the system can lose pressure, leak fluid, or even fail.

Read Also: Hydraulics and Pneumatics: Features, Differences, Examples, Advantages

What Are the Different Types of Hydraulic Fittings?

These fittings come in different shapes and sizes. Each of them is designed for specific pressures, sealing methods, and applications. Choosing the right fitting depends on the system’s requirements, thread compatibility, fluid type, and working pressure you are working with. Along with this, the connection also needs to be understood, whether it needs to be permanent or serviceable.

These are the most common hydraulic fitting types used in the field:

1. Threaded Fittings

Threaded fittings connect hydraulic parts by screwing male and female threads together. The male side has threads on the outside, and the female side has threads on the inside. Once they are tightened, they make a strong seal that keeps pressure in and fluid from leaking out.

These are the kind of fittings you’ll need in a lot of hydraulic setups, especially where some parts need to be either removed or replaced during maintenance. They’re not hard to work with, and if the threads match properly, then they’ll hold up under pressure.

Different thread types exist depending on the equipment:

- NPT is standard in North America. It seals by wedging the threads tightly.

- BSPT is similar but follows British specs, common in imported equipment.

- Metric threads are used in a lot of European and Asian machines.

Threaded fittings don’t all seal the same way. Some rely on just the threads. Others use O-rings or sealant to stop leaks. The key is knowing which one you’re working with and making sure the threads match; the wrong thread type is one of the most common causes of fitting leaks in the field.

2. Compression Fittings

Compression fittings are used to join two pipes without any welding or flaring. They work by squeezing a metal ring (called a ferrule) around the tubing when the nut is tightened. This creates a tight seal that can handle decent pressure without leaking.

These are used in systems where welding isn’t practical or safe. For example, in mobile equipment or areas where space is limited and heat can’t be applied. They’re also handy when the connection needs to be solid but still serviceable.

They’re not always the top choice for extremely high-pressure systems, but for most standard hydraulic setups, they hold up well. Easy to install, easy to replace, just make sure everything is lined up cleanly when tightening, or you will end up with a leak.

3. Flare Fittings

Flare fittings are built for high-pressure situations. The end of the tube gets flared out, usually at a 37° or 45° angle, so it fits tightly against a matching cone inside the fitting. When everything is tightened down, the metal-to-metal contact creates a strong, leak-free seal.

These fittings are common in hydraulic brake lines, refrigeration systems, and other setups where pressure and vibration are both factors. The seal holds up well under movement and stress, which is why they’re trusted in important systems.

The downside? You need the right tools to flare the tubing properly. If the flare’s uneven or cracked, it won’t seal right. But if done clearly, it’s one of the most reliable connection types out there.

Related: 10 Common Signs Your Hydraulic Hose Needs Immediate Repair or Replacement

4. Crimp Fittings

Crimp fittings are a go-to in high-pressure hydraulic systems where strength and reliability matter. The hose slips over the fitting, and then a crimping machine compresses a metal sleeve around it. Once it’s crimped, that connection is permanent; it won’t come off unless you cut it.

These are standard in heavy equipment, like excavators, loaders, and ag machines. They are built to take a beating, high pressure, vibration, and tough conditions, without letting go. The crimp holds everything tight so the hose doesn’t blow off or leak under load.

The catch is you have the right hose, the right fitting, and the right crimp specs. It’s not a one-size-fits-all deal. Get any part of it wrong and you’ll have a weak connection that won’t last. But done right, crimp fittings are one of the most durable options out there.

5. Push-to-Connect Fittings

Push-to-connect fittings are all about speed and convenience. You just push the hose or tube into the fitting, and it locks itself in place.

They are mostly used in low-pressure systems, like air lines, pneumatic tools, and light-duty hydraulics. They are great when you need to make quick changes or service something often. Just press, lock, you’re done.

The downside is that they are not built for heavy pressure or rough environments. They are simple, but that also means they’re more limited. If the hose isn’t cut square or the fitting gets dirty, you can end up with a weak seal. But when used right, they’re a fast, clean solution for lower-pressure setups.

6. Barbed Fittings

Barbed fittings are simple and effective. They have ridges, or “barbs”, that grip the inside of a hose when it’s pushed on. Usually, you secure the connection with a hose clamp to make sure it stays put.

They are mostly used in low-pressure systems like water lines, air systems, and basic hydraulic setups. You’ll see them on farm equipment, lawn machines, or anywhere the pressure is not too high and the goal is fast, affordable connections.

They are easy to install and don’t need any special tools, which is why a lot of people use them in the field. But they’re not meant for high-pressure use. If the clamp isn’t tight or the hose isn’t a good fit, you could get leaks. Still, for the right job, barbed fittings are hard to beat for simplicity.

Related: Why Custom Vinyl Tarps Are the Best Choice for Truck Covers and Outdoor Protection

Hydraulic Fittings Comparison Table

| Fitting Type | Pressure Rating | Connection Method | Tools Required | Common Use Cases |

| Threaded | Medium to High | Male/Female threads | Wrenches, sealant | Industrial machinery, fluid transfer lines |

| Compression | Moderate | Ferrule compressed by a nut | Wrenches | Mobile equipment, no-weld systems |

| Flare | High | Flared tube + nut | Flaring tool, wrench | Brake lines, refrigeration, vibration-prone |

| Crimp | High | Hose crimped to fitting | Crimping machine | Heavy machinery, construction/agriculture |

| Push-to-Connect | Low to Moderate | Push-in + lock mechanism | None | Pneumatics, shop air lines, quick changes |

| Barbed | Low | Hose over barbs + clamp | Clamp, screwdriver | Irrigation, low-pressure fluid/air systems |

What Are Hydraulic Connectors?

Hydraulic connectors are usually mentioned alongside fittings, but they serve slightly different purposes. While fittings typically refer to parts that join sections of pipe, hose, or tubing, connectors are a broader term. It can refer to any part that joins or adapts two components, including couplings, adapters, or quick disconnects.

In most systems, the terms are used interchangeably. But here’s a general way to separate them:

- Fittings- Usually threaded or sealed joints that are part of a permanent or semi-permanent hydraulic setup.

- Connectors- Includes quick-connect couplings, adapters, and sometimes specialty ends that make systems more modular or flexible.

Quick-connect hydraulic connectors are especially common in mobile equipment, where lines need to be attached or detached fast, without tools.

Most hydraulic fittings are connectors, but not all connectors are old fittings. When sourcing parts, it’s helpful to know the exact type and purpose to avoid mismatches.

Hydraulic Fitting Types Reference Chart

If you’re trying to compare different hydraulic fitting types quickly by thread, seal style, pressure, or reusability, this chart can help.

| Fitting Type | Thread Type(s) | Seal Type | Pressure Suitability | Reusable? |

| Threaded | NPT, BSPT, Metric, UN/UNF | Tapered thread or O-ring | Medium to High | Yes |

| Compression | Changes (non-thread seal) | Ferrule compression | Moderate | Yes |

| Flare | SAE 37°, 45° Flare | Metal-to-Metal | High | Yes |

| Crimp | N/A | Hose compressed to fitting | High | No |

| Push-to-Connect | Push-lock | Internal grip mechanism | Low to Moderate | Yes |

| Barbed | None | Hose + clamp | Low | Yes |

What Are the Most Common Fitting Types?

The 6 common hydraulic fitting types:

1. NPT (National Pipe Thread) Fittings

NPT fittings are used throughout North America. They have tapered threads that tighten as you screw them together. This helps in creating a pressure-tight seal. In most setups, you will still need a thread sealant or tape to stop the leaks, since the threads alone are not always enough.

You will find NPT fittings in everything from factory tools to small-scale plumbing systems. They’re simple, reliable, and work well as long as the threads are properly matched and tightened.

2. JIC (Joint Industry Council) Fittings

JIC fittings use a 37-degree flare to create a tight, metal-to-metal seal. That flare is what makes them dependable in high-pressure systems, no sealant or O-ring needed.

They are common in hydraulic lines for heavy equipment, trucks, and industrial machines. The seal holds up well against both pressure and vibration, which is why these fittings are a go-to in systems that get worked hard. As long as the flare is clean and the fitting is not overtightened, you will have a leak-free connection.

3. BSP (British Standard Pipe) Fittings

BSP fittings are mostly used in Europe, Asia, and on imported equipment. They come in two thread styles: BSPP (parallel) and BSPT (tapered).

BSPP fittings use straight threads and usually seal with a washer or O-ring. BSPT fittings are tapered, so they seal after tightening the threads together, which is similar to NPT fittings. It’s important not to mix them up, because they look similar but don’t seal the same way.

You will find BSP fittings in a range of systems, water lines, gas systems, and hydraulic setups that follow international standards. If you’re working on equipment made outside North America, there is a good chance it uses BSP threads.

4. ORFS (O-Ring Face Seal) Fittings

ORFS fittings use an O-ring that is built into the face of the fitting to create a strong, leak-proof seal. When it is tightened, the flat face of the fitting compresses the O-ring against the flat surface. This gives you a reliable connection even under high pressure.

They’re especially useful in systems that deal with pressure spikes or vibration. You will often see ORFS fittings on agricultural equipment, construction machinery, and heavy-duty industrial systems. This design cuts down on leaks, even when the system is under stress or movement.

5. Metric Fittings

Metric fittings are used in equipment that is made outside of North America, especially from Europe and Asia. They follow metric thread standards and come in a few variations, depending on the country and the system design.

These are present in manufacturing machines, imported tractors, industrial tools, and in automotive and aerospace systems. They are common because they are standardized across borders. This makes repairs and replacements easier when you are working with global parts.

Other than this, not all metric fittings are sealed with O-rings. Some of them depend on metal-to-metal contact. So, make sure you check the sealing style and thread size before swapping anything out.

6. Flange Fittings

Flange fittings are used when a hydraulic system has a larger pipe size and high pressure. These use a flat face and a set of bolts to hold everything together.

They are built for heavy-duty jobs in industrial plants, marine systems, or large construction equipment. This connection gives you a seal that can handle vibration, high flow, and extreme pressure.

Flange fittings are usually the best choice when space is limited or when you need to connect large-diameter pipes while making sure there is no thread damage or leaks. As long as the surfaces are clean and the bolts are torqued properly, they are dependable.

Related: Custom-Made Tarps vs. Standard Tarpaulin: Which One is Right for You

What Is the Standard for Hydraulic Fittings?

Hydraulic fittings have to follow a specific structure to make sure they fit right, are able to perform under pressure and keep the system safe. These are known as the standard for hydraulic fittings. Some of the most recognized standards are:

1. ISO (International Organization for Standardization)

ISO has set international standards for hydraulic fittings. This is done so that the parts that are made in different countries can work together. They cover thread size, pressure rating, sealing type, and material.

If a fitting is ISO-rated, it usually means it will work across different machines and brands without any issues. This is the standard most of the international equipment follow.

2. SAE (Society of Automotive Engineers)

SAE standards are common in North America, especially for mobile hydraulic systems like trucks, tractors, and heavy equipment. They set the specifications for fitting size, thread type, and pressure rating.

These fittings are built to handle movement, vibration, and constant use. You will see them in construction and automotive systems where reliability and easy maintenance matter. Most North American machines use SAE fittings by default.

3. DIN (Deutsches Institut für Normung)

DIN standards come from Germany and are used all across Europe. They set detailed specs for how hydraulic fittings should be made, tested, and used with a focus on precision and reliability.

You will find DIN fittings in industrial systems where tight tolerances and performance matter. If you are working on European-built machinery, there is a chance that it follows DIN standards.

Where Are Hydraulic Fittings Used?

Hydraulic fittings are used in many industries where fluid power systems are important. Their job is to connect hoses, pipes, or tubes so pressurized fluid can move through the system without leaking or dropping pressure.

Some of the common applications include:

- Construction Equipment- Excavators, loaders, backhoes, and cranes rely on hydraulic fittings to power cylinders and control systems. Crimp and flare fittings are widely used for their strength and vibration resistance.

- Agriculture- Tractors, harvesters, sprayers, and attachments all use hydraulic systems to lift, steer, and operate tools. Threaded and barbed fittings are common, based on the system’s pressure.

- Manufacturing and industrial machinery- Hydraulic presses, automatic equipment, and heavy-duty tools often use compression or threaded fittings for reliable, serviceable connections.

- Automotive systems- Brake lines, power steering, and suspension setups use flare fittings due to their ability to hold up under pressure and vibration.

Read Also: Essential Guide to Hydraulic Repair Services in Chilliwack

How to Choose The Right Hydraulic Fitting

When you are choosing a hydraulic fitting, make sure the entire connection works under pressure, matches the system specifications, and holds up over time. Getting it wrong means you will be left with leaks, dropped pressure, or system failure.

Make sure of these things when selecting a fitting:

- Thread Type:

Make sure the fitting matches your system’s thread standard. Mixing NPT, BSPT, or metric threads usually leads to cross-threading or leaks.

2. Sealing Method:

Some fittings are sealed with tapered threads, others use O-rings or flared ends. Know how your system seals and match the fitting accordingly.

3. Pressure Rating:

Always check the pressure rating on both the hose and the fitting. If the fitting is rated lower than the system, then it can become a weak point.

4. Material Compatibility:

Most hydraulic fittings are made from steel, stainless steel, or brass. Match the material to your fluid type and working environment to avoid corrosion.

5. Reusability vs. Permanent:

Crimp fittings are permanent, and threaded compression fittings can be reused. If your system needs regular servicing, consider ease of disassembly.

There’s no one-size-fits-all answer. The right fitting depends on the job, the system pressure, and how often you will be maintaining or changing out parts.

Related: How Can You Extend the Life of Your Grapple Hydraulic Cylinder?

Hydraulic Fittings Maintenance Tips

Keeping the hydraulic fittings in good shape is important. It avoids leaks, pressure drops, and unexpected breakdowns. There are a few simple practices that go a long way:

- Check for wear and leaks regularly. See if there are any signs of fluid around joints, cracks in fittings, or worn-out seals. Catching small issues early avoids bigger problems later.

- Take a look at threads and seals before reinstalling. If threads are damaged or O-rings are crushed, they can lead to poor sealing and lead to failures under pressure.

- Use the right tools. Over-tightening with the wrong wrench can strip threads or damage the fitting. Always follow torque guidelines when possible.

- Clean the area before connecting. Dirt or grit in the threads can stop fittings from sealing properly. Wipe fittings and ports before making a connection.

- Stick to matching standards. Mixing different fitting types (like NPT with BSP) might seem to work at first, but it often leads to leaks or thread damage over time.

A little maintenance goes a long way in keeping hydraulic systems running smoothly and helps extend the life of both the fittings and the equipment.

Hydraulic Hoses and Hose Fittings by Delange’s Industries

We’re Delange’s Industries, a family-owned shop in Chilliwack, BC. We’ve been working with hydraulic and pneumatic systems for over 15 years, and we know what matters: the parts that last, service you can count on, and fittings that actually fit.

We stock a full range of hydraulic hoses and fittings. These aren’t generic, one-size-fits-all parts. Everything we carry is made to handle tough conditions, be it for industrial machinery, farm equipment, or custom systems. Our fittings seal right and hold pressure the way they should. And if you’re not sure what you need, Delange’s Industries will help you figure it out.

Aside from parts, we also do repair and fabrication. If something is not working or doesn’t fit, we’ll get it sorted. That includes matching odd fittings, replacing worn hoses, or building something custom when off-the-shelf doesn’t cut it.

We’ve built our name on being straight with our customers and doing the job right. If you’re anywhere in British Columbia and need help with hydraulic gear, give us a call.

Related: Speed vs. Strength: Choosing Between Pneumatic and Hydraulic Power Systems

People Also Ask

What are hydraulic fittings used for?

Hydraulic fittings are used to connect hoses, pipes, and tubes in a hydraulic system, allowing for the efficient and safe transport of fluids under pressure.

How do I choose the right hydraulic fitting?

Selecting the right fitting involves considering the size, pressure rating, material compatibility, and the type of connection required for your system. It’s also important to match the fitting to the type of hose or pipe you’re using.

Can hydraulic fittings be reused?

Some hydraulic fittings, like reusable fittings, can be reused. However, many fittings, especially those that are crimped, are designed for single use and should be replaced after disassembly.

What’s the difference between NPT and JIC fittings?

NPT (National Pipe Tapered) fittings have tapered threads for creating tight seals, commonly used in North America. JIC (Joint Industry Council) fittings have a 37-degree flare sealing surface and are used for high-pressure applications.

Are hydraulic fittings interchangeable between different brands?

As long as the fittings meet the same standards (like ISO, SAE, or DIN) and have the same size and thread type, they can often be interchangeable. However, it’s always best to check compatibility before use.

How often should hydraulic fittings be inspected?

Regular inspection is crucial for maintaining system integrity. It’s recommended to inspect hydraulic fittings whenever you perform system maintenance or observe any signs of wear, leaks, or damage.

What causes hydraulic fittings to fail?

Common causes of failure include incorrect installation, using the wrong fitting type or size, material fatigue, excessive vibration, and corrosion.

Can I mix and match different types of hydraulic fittings?

Mixing and matching fittings is not recommended unless you’re certain they’re compatible in terms of size, thread, pressure rating, and material. Incompatible fittings can lead to leaks and system failures.

How do I prevent leaks in hydraulic fittings?

Ensuring proper installation, using the correct fitting type and size, and regular maintenance are key to preventing leaks. Also, using quality fittings and hoses appropriate for your system’s pressure and fluid type is essential.

Are there environmentally friendly hydraulic fittings?

Yes, there are eco-friendly options available that are made from sustainable materials or designed to minimize environmental impact, such as reducing fluid leaks.