Hydraulic Cylinders: A Basic to Advanced Guide

Hydraulic cylinders are crucial in many machines we see and use every day, helping them perform heavy lifting and powerful movements effortlessly. Whether it’s in construction machinery or in the mechanism of an office chair, these components ensure smooth operation.

This guide will take you through the basics of hydraulic cylinders, focusing on their design, function, and the critical role of hydraulic cylinder seals in maintaining their efficiency. Whether you’re just starting to learn about this technology or seeking to enhance your understanding, you’ll find practical insights and easy explanations here.

What are Hydraulic Cylinders?

Hydraulic cylinders are mechanical devices essential in various industries for enabling powerful and precise movements. They function by converting hydraulic fluid pressure into mechanical force.

A typical hydraulic cylinder consists of a cylindrical barrel, wherein a piston connected to a piston rod moves back and forth. This action is powered by the hydraulic fluid which is pumped into the cylinder, pushing the piston to move and carry out work.

These cylinders rely heavily on the integrity of hydraulic cylinder seals to maintain efficiency and prevent fluid leakage. Properly maintained seals ensure that the cylinder remains effective and durable over time. Hydraulic cylinders are pivotal in tasks requiring substantial force, such as in construction machinery and manufacturing processes, facilitating both heavy lifting and intricate movements with ease.

Related: Hydraulic Repair Experts Near British Columbia Canada

Components of Hydraulic Cylinders

Hydraulic cylinders are made up of several key components that work together to create motion and force. Understanding these parts is crucial for anyone looking to use, maintain, or repair hydraulic cylinders effectively. Here’s a breakdown of the main components:

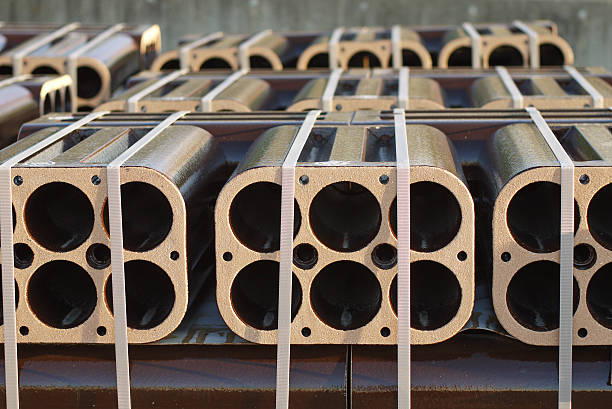

Cylinder Barrel

The cylinder barrel acts as the main body of the hydraulic cylinder, enclosing its internal components. It is designed to withstand high pressures and is usually made from robust materials like hardened steel. This component is crucial as it supports the piston and piston rod as they move within it during the cylinder’s operation.

Piston

The piston divides the interior of the cylinder barrel into two chambers. It moves back and forth, driven by hydraulic fluid pressure. The piston’s movement is responsible for the actual work performed by the cylinder, such as lifting or pushing objects. It is typically made of durable materials to withstand pressure fluctuations and wear.

Related: Expert Hydraulic Repair for Abbotsford’s Commercial and Residential Customers

Piston Rod

Extending from the piston, the piston rod exits the cylinder barrel and connects to the machinery that performs the task. The rod must be strong enough to not buckle under the force it transmits. It is often made from hardened steel and is precision-engineered to fit perfectly within the cylinder’s head to maintain pressure and prevent leaks.

Cylinder Head and Cap

The cylinder head seals the rod-end of the cylinder, while the cap closes the base end. These components are crucial for maintaining the integrity of the cylinder’s internal pressure. They also house parts of the sealing system that prevent fluid leakage from the cylinder.

Seals

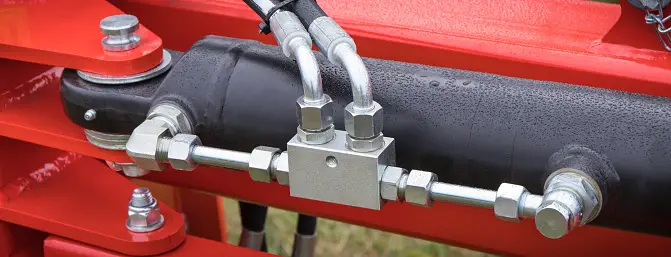

Seals are vital for maintaining the hydraulic cylinder’s efficiency. Positioned between the piston and the cylinder, and also around the piston rod, these seals prevent hydraulic fluid from leaking, ensuring that the cylinder maintains the necessary pressure to perform its tasks. They are made from materials that can withstand harsh conditions and prevent contamination.

Rod Gland

Located within the cylinder head, the rod gland includes several seals and wipers. It plays a crucial role in maintaining the cleanliness of the system by preventing external contaminants from entering the cylinder and keeping the hydraulic fluid inside from leaking out.

Ports

Ports are the channels through which the hydraulic fluid enters and exits the cylinder. They are strategically placed on the cylinder body to facilitate the controlled flow of fluid, which in turn regulates the movement of the piston. Proper port placement is critical for optimal cylinder performance.

Related: How to Achieve High-Speed, High-Force Actuation with Hydraulic Systems?

Types Of Hydraulic Cylinders

1. Tie-Rod Cylinders

Tie-rod cylinders are commonly used in the industrial sector. They are recognized by the several rods that extend from one end cap to the other, holding the cylinder together. These rods ensure stability and strength, making the cylinder suitable for high-pressure tasks. Tie-rod cylinders are favored for their ease of maintenance and repair, as the tie rods can be easily removed to service the cylinder.

2. Welded Body Cylinders

Unlike tie-rod cylinders, welded body cylinders have no tie rods. Instead, the end caps are welded directly to the barrel, providing a more compact and robust cylinder. This type is preferred in mobile applications such as agricultural machinery and construction equipment, where space is limited and durability is crucial. The lack of tie rods also makes these cylinders better suited for harsh environments where debris might interfere with tie rods.

3. Telescopic Cylinders

Telescopic cylinders are constructed with multiple stages that extend outwards, much like the sections of a telescope. This design allows them to provide a longer stroke while maintaining a shorter retracted length. They are ideal for applications requiring a long range of motion but where space constraints exist when the cylinder is not in use. Common uses include dump trucks and hydraulic lifts.

4. Mill-Type Cylinders

Mill-type cylinders are built to withstand harsh environments typical in primary metals manufacturing, foundries, and other severe service applications. They are characterized by heavy-duty construction with thicker barrel walls and reinforced end caps. These cylinders handle higher pressures and have a longer lifespan compared to other types due to their rugged construction.

5. Plunger Cylinders

Also known as ram cylinders, plunger cylinders have a piston rod that is typically larger than the piston and acts as the piston itself. These cylinders are used primarily for pushing rather than pulling, as the plunger is not capable of withstanding pulling forces. The design is simpler and often used in applications where precision and control over extensive movement are less critical.

Related: Different Types of Hydraulic Seals

How Hydraulic Cylinders Work

Hydraulic cylinders play a crucial role in various machinery by facilitating powerful and precise movements. These cylinders operate through a straightforward yet effective mechanism involving a piston, a cylinder barrel, and hydraulic fluid. Let’s break down their working process into simple steps.

The central component of a hydraulic cylinder is the piston, which is snugly fitted within the cylindrical barrel. Attached to the piston is a piston rod that extends out from one end of the cylinder, referred to as the rod end. The opposite end, which does not have the rod extending from it, is known as the blind end.

The operation of a hydraulic cylinder starts when a pump directs hydraulic fluid—usually oil—into the cylinder through designated ports. This fluid entry can occur at either end of the cylinder, depending on the desired direction of the piston’s movement.

When the fluid enters through the port at the blind end, it pushes the piston forward, which in turn extends the piston rod outward. Conversely, when the fluid enters through the port at the rod end, it causes the piston to retract, pulling the rod back into the barrel.

This fluid-driven movement of the piston allows hydraulic cylinders to exert significant force, which can be leveraged to perform various tasks such as lifting, pushing, or pulling heavy loads. The precision with which the flow of hydraulic fluid is controlled by the pump allows for meticulous management of the cylinder’s movements, making hydraulic systems incredibly efficient for tasks requiring exact force application or movement control.

Related: What Does It Take To Repair Hydraulic Cylinders?

Common Hydraulic Systems Configurations

Hydraulic systems are integral to various machinery, utilizing hydraulic cylinders to perform numerous tasks. These systems come in different configurations, each tailored to meet specific operational requirements. Understanding the common configurations can help in selecting the right system for your needs.

1. Open Center System

In an open center configuration, hydraulic fluid flows continuously between the pump and the reservoir without building pressure while the system is idle. This setup is commonly used in mobile equipment like tractors, where the fluid flows through the control valves that are connected in series and returns to the reservoir when the valves are in a neutral position. This configuration is energy efficient for applications where hydraulic functions are not constantly in use.

2. Closed Center System

Contrary to the open center, the closed center system maintains pressure within the system even when no work is being done. All control valves are arranged in parallel, and each valve can control the flow independently without affecting others. This setup is suitable for operations requiring constant hydraulic pressure and flow, such as in industrial manufacturing or heavy machinery.

3. Load Sensing System

Load sensing configurations are advanced and can adjust the hydraulic pump’s output to match the required load. This system is highly efficient as it provides the necessary flow and pressure based on the demand, reducing energy consumption and wear. It’s ideal for machinery that operates under varying load conditions, ensuring optimal performance while conserving energy.

4. Phased System

This configuration uses multiple pumps to manage different stages or phases of operation. Each pump can be activated as needed, depending on the machine’s phase of work, making it highly adaptable and efficient for complex machinery with phased operations like hydraulic presses or lifting equipment.

Related: What is Hydraulic System and its Advantages, Principles, and Applications

Maintaining Hydraulic Cylinders

Proper maintenance of hydraulic cylinders is crucial for their efficiency and longevity. Regular inspections are essential; check for signs of wear, leaks, or damage such as cracks and corrosion on the cylinder body, piston, and rod. This is especially important after periods of heavy use. Keeping the cylinders clean is also vital, as dirt and debris can severely damage the system.

Wipe off any contaminants from the cylinder, particularly around the seals and the piston rod, to prevent ingress that could lead to internal damage. It’s also important to check and replace the hydraulic fluid regularly, as old or contaminated fluid can decrease the system’s efficiency and damage components. Lastly, make sure all seals and gaskets are intact and replace any that show signs of deterioration. By following these simple steps, you can ensure your hydraulic cylinders function smoothly and last longer.

Related: Preventative Hydraulic Maintenance and Repair in Chilliwack, BC Canada

Troubleshooting Common Issues

- One of the most common issues with hydraulic cylinders is fluid leakage. Check the cylinder seals and gaskets first; if they are worn or damaged, replace them. Also, inspect the cylinder barrel and piston rod for scratches or wear that could compromise the seal.

- If your hydraulic cylinder is making unusual noises, it could be due to air in the system. Ensure that the fluid levels are correct and bleed the system to remove any trapped air.

- A cylinder that operates slower than usual might have a blockage in the fluid lines or insufficient fluid pressure. Check the hydraulic fluid levels and the condition of the hoses and lines for any blockages or leaks.

- If the piston rod is misaligned, it can wear the seals prematurely and lead to leaks or binding. Ensure that the cylinder is mounted correctly and that all mounting brackets are secure.

Benefits of Hydraulic Cylinders

1. Power and Efficiency

Hydraulic cylinders generate tremendous forces with relatively small inputs. By utilizing fluid pressure, they can perform tasks that involve lifting heavy loads, crushing materials, or operating complex machinery with ease. This efficiency is due to the way hydraulic fluid amplifies a small force applied at one point into a much larger force at another point.

2. Precision and Control

One of the standout benefits of hydraulic cylinders is their ability to achieve precise movements. Whether it’s adjusting the angle of a crane or the depth of a drill, hydraulic cylinders offer fine control over a wide range of motions. This precision is essential in applications requiring meticulous positioning, such as in manufacturing and robotics.

3. Durability and Reliability

Designed to withstand tough conditions, hydraulic cylinders are built for longevity. They are sealed units that are less susceptible to damage from dust, debris, and moisture, making them suitable for outdoor or harsh environments. Regular maintenance and replacing hydraulic cylinder seals when needed can significantly extend their lifespan.

4. Compact and Versatile Design

Despite their power, hydraulic cylinders are relatively compact compared to mechanical or pneumatic systems that might require the same force output. This compactness allows them to fit into a variety of machinery without requiring extensive modifications.

5. Cost-Effectiveness

While providing immense power and control, hydraulic cylinders also offer cost benefits. They typically require less maintenance compared to other motion-generating systems and are more energy-efficient, reducing operational costs over time.

Related: How to Easily Patch Your Tarp in just 5 Simple Steps

Advanced Hydraulic Concepts

Advanced hydraulic concepts are crucial for optimizing the performance and efficiency of hydraulic systems, especially in complex industrial applications. Here’s a brief look into some sophisticated aspects of hydraulic technology:

1. Proportional Control: This concept involves using valves that control the flow and pressure of hydraulic fluid proportionally rather than just turning on or off. Proportional control allows for finer adjustments in the speed and force of hydraulic cylinders, enabling smoother and more precise operations in machinery.

2. Electro-Hydraulic Systems: These systems combine electrical and hydraulic technologies to enhance control and versatility. Electro-hydraulic systems use electric signals to manage hydraulic operations, providing faster response times and improved efficiency, especially in automated settings.

3. Energy Efficiency Improvements: Advanced hydraulics often focus on improving energy efficiency through better system design and integration. Techniques such as using variable speed drives to control pumps can significantly reduce energy consumption by adjusting the flow and pressure to the actual needs of the operation.

4. Predictive Maintenance: With the integration of sensors and data analytics, hydraulic systems can now predict when maintenance is needed. This approach helps prevent unexpected breakdowns and extends the life of components like hydraulic cylinder seals and pumps.

Maintaining Hydraulic Systems for Optimal Performance

Keeping hydraulic systems, such as hydraulic cylinders, in top condition is crucial for their efficiency and longevity. Regular maintenance and immediate repair when needed ensure that these systems continue to perform optimally, minimizing downtime and extending the life of the machinery.

The first step in maintaining hydraulic systems is conducting regular inspections. This involves checking for any signs of wear or damage, especially to crucial components like hydraulic cylinder seals. Look for leaks, cracks, and any signs of wear that could compromise the system’s integrity. Early detection of these issues is key to preventing major failures and costly repairs.

It’s also important to ensure that the hydraulic fluid is at the correct level and is clean. Hydraulic fluid plays a critical role in the smooth operation of the system, and any contamination could lead to inefficiency and damage. Replace the fluid and clean or replace filters regularly to maintain the system’s health.

Another critical aspect is the maintenance of the hydraulic cylinder itself. Ensure that all connections are secure and that there are no obstructions that could affect the cylinder’s movement. Regular servicing should include checking and replacing worn parts, such as seals and rods, to prevent malfunctions.

For effective and reliable hydraulic service and repair, partnering with a reputable service provider. Delanges Industries can make a significant difference. We offer expert services in hydraulic cylinder repair and general hydraulic maintenance, ensuring that your systems are serviced by professionals who understand the intricacies of hydraulic technologies.

Adopting a proactive maintenance schedule helps to reduce the risk of unexpected breakdowns, ensures safety, and maintains the performance of hydraulic systems. This approach not only saves time and money but also enhances the overall productivity of your operations.

Related: Expert Hydraulic Repair Services in British Columbia: Ensuring Efficiency and Reliability

Wrapping Up

Keeping hydraulic cylinders in good shape is key to making sure your machinery works smoothly and lasts longer. Regular checks and cleaning, along with timely repairs, are crucial to avoid costly fixes and downtime. Whether it’s changing worn-out seals or making sure the fluid levels are right, each maintenance task helps keep your hydraulic systems running well.

Delanges Industries provides expert on-site hydraulic repair and maintenance services in Chilliwack, and across British Columbia, Ensuring your equipment always performs at its best. Remember, looking after your hydraulic cylinders properly not only extends their life but also boosts your overall productivity.

People Also Ask

What is a hydraulic cylinder?

A hydraulic cylinder is a mechanical actuator used to provide unidirectional force through a unidirectional stroke. It utilizes hydraulic fluid to convert energy into mechanical force.

How do you maintain hydraulic cylinders?

Maintaining hydraulic cylinders involves regular inspections for leaks and damage, changing the hydraulic fluid periodically, and checking the integrity of seals and joints to ensure optimal performance.

What are common problems with hydraulic cylinders?

Common issues include leakage due to worn seals, contamination of hydraulic fluid, cylinder rod scratches, and misalignment, all of which can affect the cylinder’s efficiency and longevity.