Different Types of Grapple Hydraulic Cylinders: Quick Guide

Hydraulic cylinders are like strong arms that help machines move, lift, and grab things. One special type is called a grapple hydraulic cylinder. Grapples are used everywhere in forests for picking up logs, on farms to move hay, in recycling yards to lift scrap, and even on construction sites to handle big rocks and waste. But not every grapple hydraulic cylinder is the same. Some are strong for heavy lifting, while others are quick and easy to control. Knowing the right type can help you do your work better, safer, and faster. In this quick guide, we will learn different types of grapple hydraulic cylinders in a very simple way. This will help you choose the best one for your needs, especially in tough weather and working conditions.

What is a Grapple Hydraulic Cylinder?

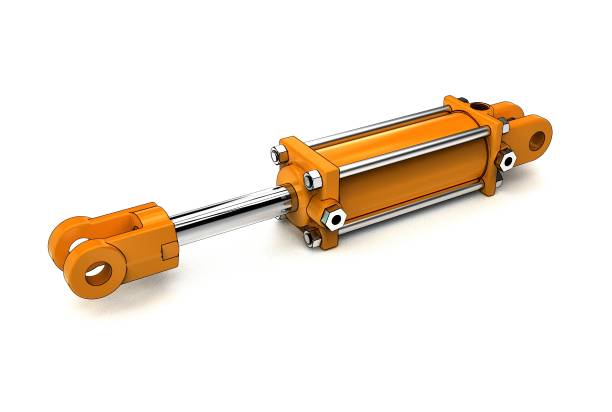

A grapple hydraulic cylinder is a strong metal part that helps big machines hold, lift, and move things easily. Just like a powerful metal arm that can grab heavy things tightly, like logs in a forest, metal scraps at a recycling centre, or big rocks at a construction site. It uses oil pressure to push and pull, making the grapple open or close its grip.

Inside a grapple hydraulic cylinder, there is a rod connected to a piston. When oil enters one side of the cylinder, it pushes the piston and makes the grapple arm close, holding the item firmly. When oil goes into the other side, it pulls the piston back, opening the grapple again to release the item.

These cylinders are used a lot, especially because of the heavy-duty jobs in farming, forestry, recycling, and construction. They help machines do hard work quickly and safely, even in cold and snowy weather. Using the right grapple hydraulic cylinder means your machine will last longer and do its job better.

Related: Hydraulic vs. Mechanical Grapples: Which One Should You Choose?

Types of Grapple Hydraulic Cylinders

Grapple hydraulic cylinders come in many types. Each type is good for different jobs. Let’s first understand the simplest type: Single-Acting Hydraulic Cylinders.

1. Single-Acting Hydraulic Cylinders

A single-acting hydraulic cylinder is a basic type of hydraulic cylinder. It has a piston inside which moves in only one direction, mostly outward. Imagine pushing a bicycle pump; it pushes air in only one way. The same happens here: oil pushes the piston out, but it cannot pull it back inside.

Single-acting grapple cylinders are commonly found in small grabbers. Farmers often use these small grapples to lift and move hay bales, branches, or garden waste. When the cylinder pushes forward, the grapple closes tightly around the object. To open the grapple again, a spring or gravity helps pull it back.

Pros of Single-Acting Grapple Hydraulic Cylinders

- Simple Design: Because the cylinder has fewer parts, it is easy to understand and use, even if you are new to hydraulic systems.

- Easy to Repair: With fewer moving parts, fixing problems is quick and does not need special tools or training.

- Low Cost: They are usually cheaper because they are easier to make and maintain, ideal for small farms or businesses with limited budgets.

Cons of Single-Acting Grapple Hydraulic Cylinders

- Moves Only One Way: The cylinder can only push outwards. To return, it relies on gravity or springs. This limits precise control.

- Less Power and Control: Not suitable for heavy or complicated jobs because you cannot fully control opening and closing actions.

- Limited Usage: Good only for simple and lightweight tasks, like moving small logs or hay. Bigger and heavier jobs will require a stronger type of cylinder.

In short, single-acting hydraulic cylinders are great for simple, everyday grapple tasks in Canada, especially when ease of maintenance and lower costs matter most. For heavy or precise tasks, other cylinder types like double-acting cylinders would be better.

2. Double-Acting Hydraulic Cylinders

A double-acting hydraulic cylinder is a powerful cylinder that moves both ways—in and out. This means it can push and pull using hydraulic oil. Imagine using your arms to open and close a heavy gate: you push to open it and pull it back to close it. A double-acting cylinder works just like that. Oil pressure pushes the piston forward to close the grapple and then pulls it back inside to open it again. This allows the grapple to hold tightly and also release things quickly.

How Double-Acting Cylinders Help Grapples

Double-acting cylinders give grapples a strong and controlled grip. When the machine grabs a heavy item, such as a large tree log or big pile of metal scraps, the cylinder pushes out with great force to close the grapple firmly. Because it moves both ways, the grapple can also open easily, even if it’s holding heavy or awkward items. This strong control makes double-acting grapple cylinders excellent for tasks that need careful handling and precision.

In Canada, where heavy-duty work like forestry, recycling, and construction often happens in tough conditions, double-acting hydraulic cylinders help machines perform better. These cylinders can handle heavy lifting in all types of weather, including cold Canadian winters, when equipment needs extra power and reliability.

Where Double-Acting Grapple Cylinders Are Mostly Used

Double-acting hydraulic cylinders are mostly used on bigger machines that do heavy and precise jobs. They are popular in:

- Forestry Grapples: Machines picking up heavy logs and branches in Canadian forests use double-acting cylinders to hold logs tightly without dropping them, making logging safe and fast.

- Recycling Grapples: Recycling centres use double-acting cylinders on grapples to lift and move heavy scrap metal, cars, or waste materials easily and safely.

- Construction Grapples: Construction workers use these cylinders to pick up large rocks, concrete, and building materials. The strong and controlled movement ensures items don’t slip or fall, protecting workers and equipment.

Pros of Double-Acting Grapple Hydraulic Cylinders

- Powerful Grip: They grip and hold heavy things securely, making jobs safer and faster.

- Flexible Control: Double-acting cylinders offer better control because they can easily open and close, perfect for precise tasks.

- Good for Heavy Jobs: They work well on bigger machines handling heavy materials, ideal for forestry, recycling, and construction.

Cons of Double-Acting Grapple Hydraulic Cylinders

- More Parts Needed: Double-acting cylinders have more parts inside, making them slightly harder to fix if they break.

- A Bit Expensive: These cylinders cost more because they are stronger, more complicated, and offer more control. Businesses with smaller budgets might find them costly to buy and maintain.

Are Double-Acting Grapple Cylinders Right for You?

If your job involves heavy or precise work, double-acting hydraulic cylinders are usually the best choice. They give your machines the strength and control they need, especially in harsh weather conditions. However, if your tasks are smaller or simpler, you might prefer single-acting cylinders, as they cost less and are simpler to manage.

In short, double-acting grapple hydraulic cylinders offer strong performance, precise control, and are excellent for heavy-duty work. They may cost a bit more, but the benefits for big tasks usually make them worth the investment for Canadian users.

Related: How Canadian Tarps Are Designed for the Great Outdoors

3. Telescopic Hydraulic Cylinders

Telescopic hydraulic cylinders are special types of cylinders that open up like a telescope, extending section by section. Imagine an old-style telescope that sailors use—it starts small and compact but can stretch out very far when opened. These cylinders work exactly like that. They have sections inside, each smaller than the other, which push out one after another to become very long. This unique feature allows them to reach further distances compared to regular hydraulic cylinders.

How Telescopic Cylinders Help Grapples in Construction and Forestry

Construction and forestry jobs often require machines to reach far or high up. Telescopic hydraulic cylinders are perfect for this because of their ability to extend longer distances than regular cylinders.

- Construction Sites: On construction sites, machines use telescopic grapple hydraulic cylinders to reach over barriers, deep into pits, or high above buildings. For example, if workers need to clear debris from a deep hole or lift materials onto a high platform, a telescopic cylinder helps the grapple extend its reach easily. It can pick up heavy items safely, even when they are far away or at a difficult angle.

- Forestry Work: In forestry, telescopic cylinders help grapples reach logs that are located further away or stacked high up. Canadian forests often have rough terrain and logs can be in hard-to-reach areas. Telescopic grapple cylinders allow machines to reach these logs easily without needing to move closer. This saves time and keeps workers safe by reducing the need to go near dangerous spots or unstable ground.

Pros of Telescopic Grapple Hydraulic Cylinders

- Long Reach: The biggest advantage of telescopic hydraulic cylinders is their long reach. They can easily extend further than regular cylinders, making difficult tasks much simpler and safer.

- Saves Space When Closed: When not in use, telescopic cylinders fold down neatly, taking up less space. This compact size makes them easier to store and transport, and also protects them from damage when not being used.

- Flexible for Difficult Tasks: Because they can reach far and high, telescopic cylinders are excellent for tricky or hard-to-access tasks, especially in Canadian forestry and construction industries.

Cons of Telescopic Grapple Hydraulic Cylinders

- Higher Cost: One downside of telescopic hydraulic cylinders is their higher price. Their complex design and special parts mean they cost more initially compared to simpler cylinders like single-acting or double-acting types. Smaller businesses or farms might find them costly to buy or replace.

- Needs Careful Maintenance: Because of their complex structure, telescopic cylinders need regular care and checks. Each section inside must be carefully maintained, cleaned, and lubricated. Without proper care, these cylinders might jam, leak, or become damaged, especially during cold Canadian winters. Regular checks and careful handling are important to keep them working smoothly.

Are Telescopic Grapple Hydraulic Cylinders the Right Choice?

If your job in Canada involves reaching very far, very high, or working in tricky places, telescopic grapple hydraulic cylinders are a smart choice. Their long reach and flexibility help you finish difficult jobs faster and safer. However, remember they require careful care and are usually more expensive.

In short, telescopic hydraulic cylinders offer great reach and flexibility, ideal for forestry and construction. But they also require regular attention and a higher initial investment. Choose this type only if your tasks truly need the extended reach and you’re prepared for regular upkeep.

4. Tie-Rod Hydraulic Cylinders

Tie-rod hydraulic cylinders are a type of hydraulic cylinder that use strong metal rods to hold everything together. Think of it like a strong steel sandwich—the rods keep the cylinder tightly in place, making sure nothing moves or breaks apart even during heavy work. These rods run along the outside of the cylinder, keeping the inside parts safe and secure.

How Tie-Rod Cylinders Are Used in Grapple Equipment

Tie-rod hydraulic cylinders are very popular in grapple equipment because they are strong, tough, and reliable. Grapples need powerful cylinders to grip tightly and lift heavy items like big rocks, logs, or piles of construction materials. Tie-rod cylinders handle these tough jobs easily.

Because these cylinders have rods holding everything securely, they can deal with heavy loads without bending or breaking. For example, in Canada, tie-rod cylinders are used widely in machines that lift heavy construction materials on building sites or pick up big hay bales on farms. Their solid construction helps grapples work safely and steadily even under heavy stress or tough weather conditions, such as snow or freezing temperatures.

Common Uses of Tie-Rod Grapple Cylinders

- Farm Grapples: Farmers use tie-rod hydraulic cylinders in grapples to move hay bales, animal feed, and other heavy farming supplies. These cylinders help machines grip and carry items safely without dropping them, even across rough farm terrain.

- Construction Grapples: Tie-rod cylinders are widely used in construction equipment. They help grapples move large rocks, concrete blocks, and building materials safely. Because construction work is often heavy and difficult, having reliable tie-rod cylinders ensures machines perform consistently and safely.

Pros of Tie-Rod Grapple Hydraulic Cylinders

- Easy to Fix: One big advantage of tie-rod hydraulic cylinders is how easy they are to repair. The rods are simple to remove, which means if any part inside the cylinder breaks or leaks, it can be fixed quickly without special tools or complicated methods.

- Very Tough and Durable: Tie-rod cylinders are strong and designed for tough jobs. They can handle heavy materials and rough conditions, making them ideal for farming and construction environments, which often face challenging weather and heavy workloads.

- Reliable Performance: Because these cylinders are held securely by tie-rods, they deliver consistent and reliable performance, helping businesses avoid downtime and costly delays.

Cons of Tie-Rod Grapple Hydraulic Cylinders

- Heavy Weight: A downside to tie-rod cylinders is their weight. The rods and strong materials make the cylinder heavier, which might affect the machine’s overall weight. Heavy cylinders can make some machines less flexible or slower when moving around job sites.

- Takes More Space: Tie-rod cylinders are bigger because of the rods outside. This can cause problems when space is limited or when you need a compact design for tight working areas. The extra space needed might limit their use on smaller machines or in very tight locations.

Should You Choose Tie-Rod Grapple Hydraulic Cylinders?

If you need a strong, reliable cylinder that’s easy to repair and handle heavy workloads, then tie-rod grapple hydraulic cylinders are a good choice. Canadian construction sites, farms, and other tough environments benefit from the durability and ease of maintenance these cylinders provide.

However, if your machine requires a lighter or more compact cylinder, you might prefer welded cylinders or other types instead. Tie-rod cylinders work best when toughness, easy repair, and reliability are your top priorities, especially for heavy-duty Canadian tasks.

In short, tie-rod hydraulic cylinders are sturdy, simple to fix, and extremely reliable. While they do take more space and add weight to your equipment, the toughness and ease of maintenance usually outweigh these drawbacks, especially in demanding farming and construction settings.

5. Welded Hydraulic Cylinders

Welded hydraulic cylinders are strong cylinders built by welding metal parts directly together without using any rods or screws. These cylinders are made into a single, solid piece, making them very tough and reliable for heavy lifting tasks. Because of their welded construction, they handle difficult and demanding jobs easily, offering excellent strength, durability, and long-lasting performance. Welded hydraulic cylinders are widely used in heavy-duty work like construction, forestry, and recycling.

How Welded Cylinders Help Grapples

Welded cylinders are very popular for grapple equipment because they are tough and reliable. They provide great strength, especially in heavy-duty jobs like lifting large logs, moving heavy metal scraps, or handling big construction materials. These cylinders do not have rods or bolts sticking out, which makes them stronger and less likely to break or get damaged during heavy lifting.

When a grapple needs to hold onto something very heavy, a welded cylinder helps the grapple grab it tightly and lift it safely. This makes welded cylinders ideal for tasks in difficult working conditions, such as rough Canadian forests, busy construction sites, or heavy recycling yards. They provide consistent strength, even when working long hours or handling difficult tasks.

Common Uses of Welded Grapple Hydraulic Cylinders

Welded hydraulic cylinders are mostly used in places where heavy lifting and tough jobs happen regularly:

- Construction Grapples: Construction workers often use welded cylinders to handle heavy materials such as steel beams, concrete, or large rocks. Because welded cylinders are strong and durable, they help construction machines do their work safely and effectively, even in bad weather conditions.

- Logging Grapples: In logging operations, welded cylinders help grapples lift large, heavy logs safely. They can withstand the rough use and heavy lifting required in logging without breaking or wearing down quickly.

- Heavy-Duty Recycling Grapples: Recycling yards handling heavy metal scraps, cars, or heavy waste materials rely on welded hydraulic cylinders. These cylinders are robust enough to pick up heavy loads without losing power, ensuring efficient and safe operations.

Pros of Welded Grapple Hydraulic Cylinders

- Very Durable: Because welded cylinders have no loose parts like rods or bolts, they last longer and rarely break down. They handle tough tasks easily without getting damaged quickly.

- Compact Size: Welded cylinders are smaller and compact because they don’t have extra parts sticking out. This makes them ideal for machines where space is limited. They fit easily into tight spaces on grapples, allowing better movement and easier handling in crowded or small job areas.

- Strong Performance: Welded cylinders deliver powerful performance consistently. They are reliable in heavy-duty jobs, providing the strength and support needed for grapples to handle heavy loads safely and effectively.

Cons of Welded Grapple Hydraulic Cylinders

- Harder to Repair: One disadvantage of welded cylinders is that they are more difficult to fix. Since the parts are welded together, repairs usually need special equipment and skills. If something breaks inside the cylinder, you might need professional help, making repairs more costly and time-consuming compared to tie-rod cylinders.

Should You Choose Welded Grapple Hydraulic Cylinders?

If your job involves heavy lifting, rough handling, or working in challenging Canadian conditions, welded grapple hydraulic cylinders are often the best choice. They are strong, compact, and reliable, perfectly suited for tough jobs in logging, construction, and heavy-duty recycling.

But keep in mind, welded cylinders require expert repair services when something goes wrong. If you prefer cylinders that are easier and quicker to repair yourself, you might choose tie-rod cylinders instead.

In short, welded hydraulic cylinders offer unmatched durability, compact size, and powerful performance, making them excellent for demanding jobs. Just remember that repairs can be more complicated, needing professional help to keep your equipment running smoothly.

Related: Services You Didn’t Know a Hydraulic Shop Could Offer

Choosing the Right Grapple Hydraulic Cylinder

Selecting the correct grapple hydraulic cylinder can make a big difference in how smoothly your machinery works. Because grapples are used across many tough industries, such as forestry, farming, recycling, and construction, picking the right cylinder ensures efficiency, safety, and long-term reliability. Here are some clear, simple points to help you choose the best grapple hydraulic cylinder for your specific job:

Job Type (Forestry, Farming, Recycling, Construction)

The first thing to consider when choosing a grapple hydraulic cylinder is the type of work you are doing:

- Forestry Work:

Grapples used in forestry often lift heavy logs and branches. A strong cylinder, like a welded or double-acting cylinder, works best here because it provides the power and control needed to hold heavy logs tightly without dropping them. - Farming Tasks:

Farming usually involves lifting lighter loads, like hay, feed, or manure. Single-acting or tie-rod cylinders are good choices here because they are cost-effective, easy to fix, and reliable for routine jobs. - Recycling Industry:

Recycling centres handle a lot of heavy materials, like scrap metal and waste. Welded cylinders or double-acting cylinders are suitable for recycling tasks because they offer strong grips and reliable performance when moving heavy, awkward items repeatedly. - Construction Projects:

For construction work, consider double-acting or welded hydraulic cylinders. These provide precise control, powerful grip, and high reliability when lifting materials like concrete blocks, steel beams, or large rocks.

Cylinder Size (Long or Short Reach)

Another important factor to consider is the cylinder size and reach:

- Long Reach (Telescopic Cylinders):

If you need to reach far distances or high places—common in construction sites and forestry work—choose telescopic cylinders. They stretch out far, allowing grapples to pick up objects located at a distance or height without needing to reposition machinery frequently. - Short Reach (Single or Double-Acting Cylinders):

If your tasks are closer and don’t require extra reach, simpler cylinders such as single or double-acting ones are ideal. They offer sufficient strength, quicker operation, and easier handling for shorter distances and lighter tasks, like farm work or simple construction jobs.

Budget (Cheaper or More Durable Options)

Your budget plays a big role in your choice:

- Cheaper Options:

Single-acting and tie-rod cylinders are usually less expensive. They have simple designs, fewer parts, and cost less to repair. These cylinders are ideal if your budget is limited and your tasks are lighter or less demanding. - Durable Options:

Welded cylinders or double-acting cylinders cost more initially, but their strong construction and long-lasting performance make them a better investment in the long run, especially for heavy or frequent use. Choosing these cylinders saves money over time because they last longer and reduce frequent replacement costs.

Maintenance Level Needed

Different cylinders require different levels of maintenance:

- Low Maintenance (Single-Acting and Tie-Rod Cylinders):

Single-acting and tie-rod cylinders are easy to fix and maintain because of their simpler design. Regular checks, basic lubrication, and quick repairs are usually all they need. This makes them perfect for smaller operations or farms where maintenance skills might be limited. - Regular or High Maintenance (Telescopic and Welded Cylinders):

Telescopic cylinders need careful cleaning and regular lubrication due to their multiple moving parts. Welded cylinders, while tough, need professional help for repairs because of their sealed, welded construction. Choose these cylinders only if you have access to regular professional maintenance or can handle detailed routine checks.

Quick Recap – To Make the Right Choice

To pick the best grapple hydraulic cylinder for your needs, always consider:

- Job Requirements: Choose the cylinder type according to your work—forestry, farming, recycling, or construction.

- Cylinder Size and Reach: Decide if you need a cylinder with a longer reach or a shorter, more compact design.

- Your Budget: Balance cost against durability. Cheaper cylinders work well for small or infrequent tasks, while more expensive cylinders provide better long-term value for heavy use.

- Maintenance Capability: Make sure you can handle the maintenance required. Low-maintenance options suit small businesses, whereas higher-maintenance cylinders are better for professional settings with access to skilled repairs.

Taking time to understand these points helps you choose the grapple hydraulic cylinder that will do the best job for you. This ensures your Canadian business or farming operation remains safe, efficient, and cost-effective, even in challenging working conditions.

Simple Maintenance Tips for Grapple Hydraulic Cylinders

Taking care of your grapple hydraulic cylinder is important if you want your machines to keep working properly. Regular care helps avoid costly repairs and ensures your grapple performs well even in tough Canadian weather. Here are five simple, clear tips to maintain your grapple hydraulic cylinders effectively:

1. Check for Leaks Regularly

Always keep an eye out for leaks. Leaks happen when hydraulic oil starts to drip from the cylinder or hoses. If you see oil leaks, it’s a sign something is wrong. Even small leaks can cause your grapple to lose strength over time and lead to bigger problems. To prevent leaks, tighten loose fittings or replace worn-out seals as soon as you notice them.

2. Keep Cylinders Clean from Dirt and Snow

Dirt, mud, ice, and snow are common challenges. Dirt and snow that gather around your grapple hydraulic cylinder can damage the cylinder’s seals or scratch the metal surfaces, causing leaks or weakening the cylinder. Clean your cylinder regularly by wiping away dirt, mud, ice, and snow. Keeping the cylinder clean helps it run smoothly and reduces the risk of costly repairs.

3. Lubricate Moving Parts Regularly

Regular lubrication keeps your grapple hydraulic cylinder working smoothly. Proper lubrication reduces friction (the rubbing of metal parts together), which means your cylinder lasts longer and runs better. Use the right lubricant recommended by the cylinder manufacturer. Remember to lubricate moving parts like rods, pivots, and joints regularly, especially before and after heavy use or when operating in extreme cold or wet conditions.

4. Inspect Cylinder Rods for Damage

The cylinder rod (the shiny metal part that moves in and out) must be smooth and free of scratches or dents. Damaged rods can cause leaks and even damage the cylinder seals. Regularly check rods for any marks, rust, or damage. If you notice any scratches or dents, have them repaired or polished immediately. Regular rod inspections help avoid expensive replacements and downtime.

5. Check Oil Levels and Oil Condition Frequently

Hydraulic cylinders rely on clean oil at the right level to work properly. Regularly check the hydraulic oil level to ensure it’s not too low. Low oil can cause your grapple cylinder to lose power, while dirty oil can harm the cylinder from the inside. Change the oil regularly according to your cylinder manufacturer’s guidelines, and always use the recommended type of hydraulic oil.

Quick Recap – Keeping Your Grapple Hydraulic Cylinders Healthy:

- Regularly check for oil leaks and fix them quickly.

- Keep your cylinders clean by removing dirt, mud, snow, and ice.

- Lubricate moving parts often to keep your cylinders running smoothly.

- Inspect cylinder rods regularly and fix any damage right away.

- Check oil levels frequently, keep oil clean, and use the correct oil type for cold Canadian winters.

Related: The Basics of Hydraulic Repair: What Every Equipment Owner Should Know

Frequently Asked Questions About Grapple Hydraulic

- What size grapple hydraulic cylinder do I need?

Choose cylinder size based on your grapple’s job. Smaller cylinders (2-3 inches diameter) suit lighter tasks like farm use, while larger cylinders (4-6 inches diameter) handle heavy forestry, construction, or recycling jobs effectively. - How do I know if my grapple hydraulic cylinder is broken?

Check for signs like leaking oil, weak or slow movements, strange noises, or visible damage to cylinder rods or seals. These are common signs your grapple hydraulic cylinder needs repairs. - Are grapple hydraulic cylinders easy to fix?

Single-acting and tie-rod cylinders are easy to fix because of their simpler designs. Welded and telescopic cylinders usually require expert repairs, as they’re more complicated and need special tools. - Can grapple hydraulic cylinders be used in cold Canadian weather?

Yes, grapple hydraulic cylinders work well in Canadian winters, especially when using the correct hydraulic oil designed for cold temperatures. Regular maintenance and proper lubrication ensure smooth operation in cold conditions.

Wrapping Up

Choosing the right grapple hydraulic cylinder ensures your machines work smoothly and safely, even in tough Canadian weather. Single-acting cylinders suit simple tasks, while double-acting, telescopic, tie-rod, and welded cylinders handle heavy or complex jobs reliably. Regular checks, proper cleaning, and careful maintenance help cylinders last longer and save you money. For trusted hydraulic repair and service, contact Delanges Industries, we’re here to keep your grapple hydraulic cylinders performing at their best.